Product Description:

1. This product is divided into three-phase and single-phase, and is iron core dry type;

2. The core is made of ultra-thin high-quality cold-rolled silicon steel sheets, which are punched and sheared by high-speed punching machines. It has small burrs, uniform and regular laminations, and neat and beautiful laminations, ensuring the low temperature rise and low noise performance of the reactor during operation;

3. The coil is made of high-quality H-class insulated wire, wound by a special machine, and has the advantages of good flatness and beautiful appearance;

4. During the reactor assembly process, all clips are treated with anti-corrosion, key clips are made of non-magnetic materials, and go through the process of pre-baking - vacuum varnishing - hot baking and curing, so that the reactor coil and iron core are firmly integrated, greatly reducing the temperature rise and noise during operation, and effectively improving the quality factor of the reactor;

5. The reactor dimensions are designed with reference to the standard cabinet dimensions. It is small in size and convenient for wiring, saving the user's cabinet investment cost.

- Application

- Features

- Conditions of Use

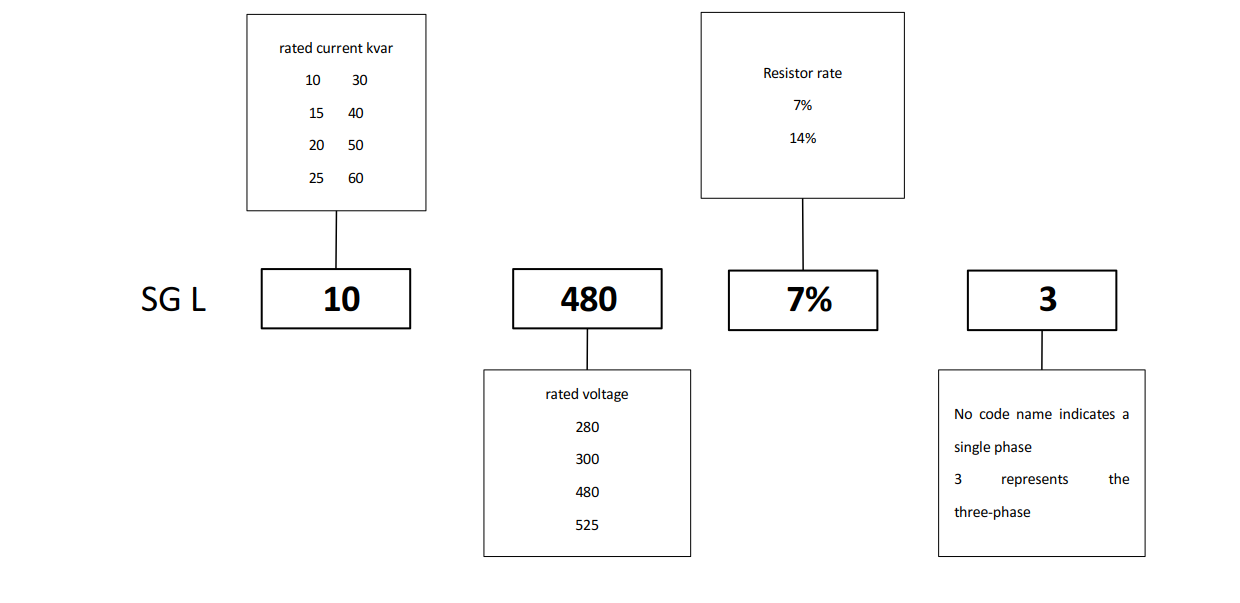

- Quick Selection Table

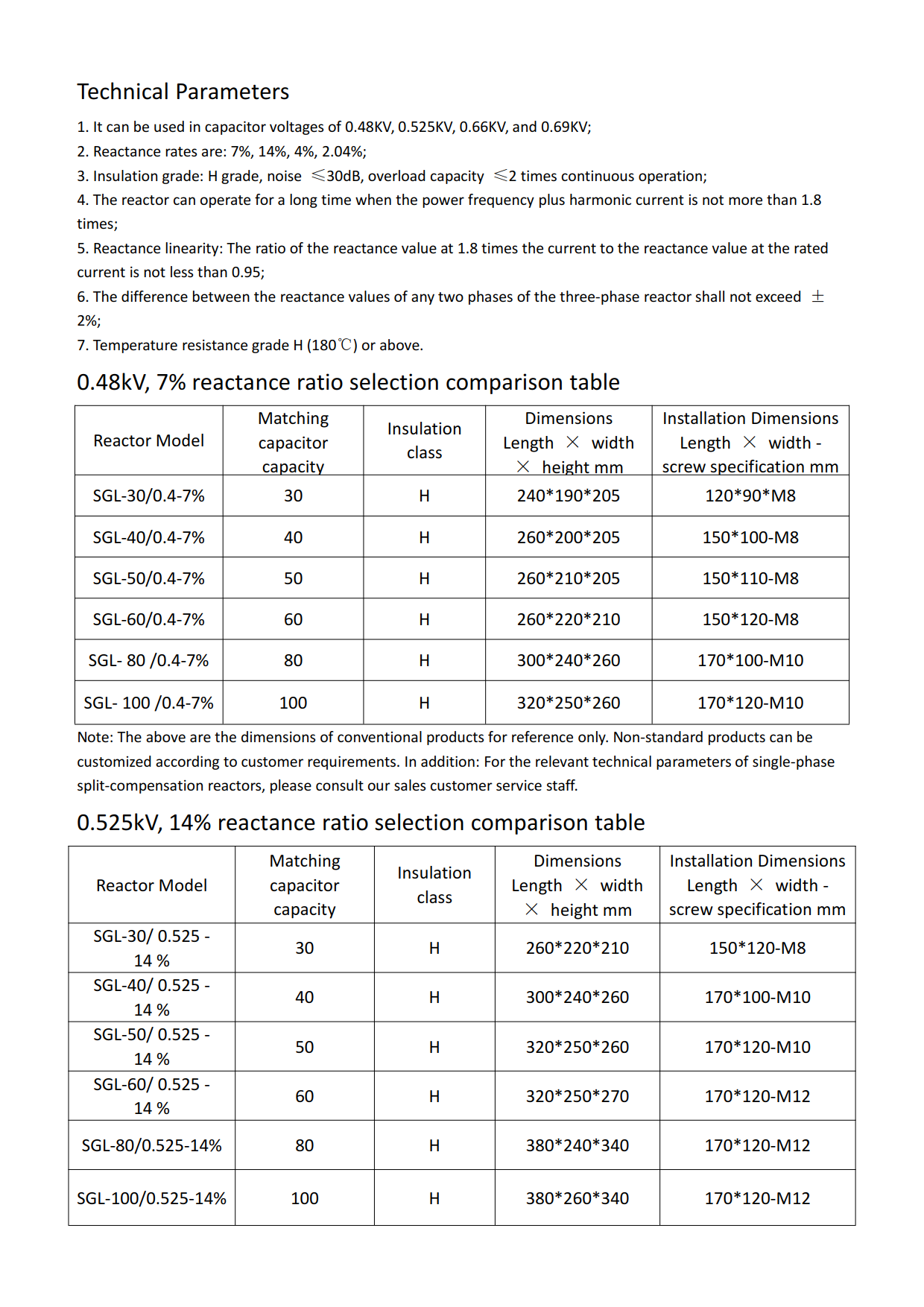

- Technical Parameters

When compensating for capacitive reactive power, capacitors are often affected by harmonic currents, closing inrush currents and operating overvoltages, causing capacitor damage and reduced power factor. For this reason, it is necessary to install a series reactor in front of the capacitor to suppress and absorb harmonics, protect the capacitor, avoid the influence of harmonic voltage and current and impact voltage and current, improve power quality, increase system power factor, extend capacitor life, and ensure safe operation of the power grid.

1. This product is divided into three-phase and single-phase, and is iron core dry type;

2. The core is made of ultra-thin high-quality cold-rolled silicon steel sheets, which are punched and sheared by high-speed punching machines. It has small burrs, uniform and regular laminations, and neat and beautiful laminations, ensuring the low temperature rise and low noise performance of the reactor during operation;

3. The coil is made of high-quality H-class insulated wire, wound by a special machine, and has the advantages of good flatness and beautiful appearance;

4. During the reactor assembly process, all clips are treated with anti-corrosion, key clips are made of non-magnetic materials, and go through the process of pre-baking - vacuum varnishing - hot baking and curing, so that the reactor coil and iron core are firmly integrated, greatly reducing the temperature rise and noise during operation, and effectively improving the quality factor of the reactor;

5. The reactor dimensions are designed with reference to the standard cabinet dimensions. It is small in size and convenient for wiring, saving the user's cabinet investment cost.

1. The altitude shall not exceed 2,000 meters;

2. The operating environment temperature is -25℃~-45℃, and the relative humidity does not exceed 90%;

3. There are no harmful gases and flammable and explosive items around;

4. The surrounding environment should have good ventilation conditions. If installed in a cabinet, ventilation equipment should be installed.